Powder Coating vs Painting, What's the Difference

There seems to be only a one-word difference between powder coating and spray painting, so many people will confuse them as different names for the same process, but this is not actually the case.

In principle, spray paint is the use of compressed air will be liquid paint (paint), dispersed into a mist form adhering to the surface of the coated object, after drying or drying, the formation of a layer of paint film.

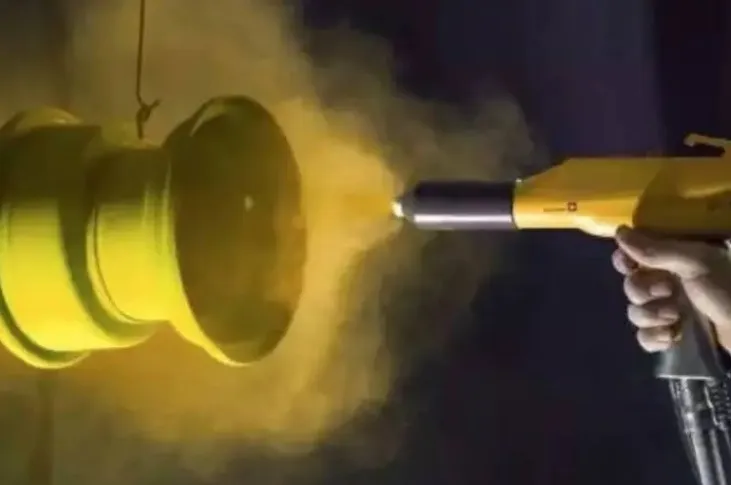

The working principle of powder spraying, not atomisation, but the electrostatic field adsorption, powder in the electrostatic gravitational force and the role of air flow sprayed on the workpiece, after heating and curing into a film.

For example, powder coating electrostatic spraying, its working principle is that the electrostatic spray gun front end with a high-voltage electrostatic generator, the resulting high-voltage corona discharge will be generated in the vicinity of the spray gun charge, powder through the gun from the nozzle when sprayed, constituting a circuit to form the charged paint particles, under the action of the electric field, the powder will be adsorbed into the workpiece of the polarity of the opposite up.

The more powder attached to the workpiece, the more the charge will be, when it reaches a certain thickness, due to electrostatic repulsion, it is no longer adsorption, so that the entire workpiece to obtain a certain thickness of powder coating, forming a more uniform coating film.

In addition to different working principles, the two processes used in the paint is also very different.

The paint used in the spray painting process is mainly paint, and in terms of status, it can be divided into ‘water-based paint,’ which uses water as a solvent, and ‘oil-based paint,’ which uses dry oil as the main film-forming substance.

Oil-based paints are more closed and abrasion-resistant than water-based paints, but the highly dispersed paint mist and evaporated solvents are more polluting to the environment, and their environmental friendliness is relatively low.

The powder coating used in the powder spraying process is a completely different form from the general paint, which exists in the state of micro-fine powder and is mainly divided into two categories: thermoplastic powder coating and thermosetting powder coating. Among them, the development of thermosetting powder coatings is particularly rapid.

Product Make-up Artist for Manufacturing

If the welding process is to build the skeleton of the product, then powder coating is to dress the product.

Whether it is the appearance of metal products, or the decoration of industrial products, those who need surface treatment of metal products, may see the figure of this process.

In Yirui's own manufacturing line, every year, a large number of shelf products, also need to go through the powder coating process of shaping, in the production line for appearance upgrade.

The process of powder coating can be simply summarised as ‘seven parts washing, three parts spraying’. Covering the surface of the product with paint is only one part of the process, and a series of pre-treatment procedures have to be carried out before spraying the paint.

In Yirui's own manufacturing line, through degreasing, descaling, phosphating and washing between processes, all kinds of foreign substances (such as oil, rust, dust, etc.) attached to the surface of the blank workpiece are removed before painting.

Powder coating is more than just good looks

The role of powder coating, most people's perception is to give items a brilliant colour, but from the point of view of industrial manufacturing, the colour is actually a secondary need, anti-rust and anti-aging is the main purpose.

Due to the characteristics of the material, wood is easy to rot, metal is easy to aging rust, the use of powder coating surface treatment process, can better protect the raw material, improve the service life of various industrial products, thus saving the purchase cost for customers.

Of course, this is common to all surface treatment processes, so what are the unique characteristics of powder coating? We may be able to elaborate from the environmental protection, efficiency and finish three perspectives.

As mentioned above, most paints and coatings contain organic solvents, such as alcohols, ketones, ethers, etc., the environment and the human body have a certain degree of damage.

Powder coatings, on the other hand, do not contain organic solvents, and the coating process does not produce solvent vapour, which is less polluting to the environment and does not involve difficulties such as exhaust emission control.

In addition, powder coating is solid powder, can be used in a closed-circuit recycling system, the oversprayed powder coating for recycling and reuse, paint utilisation rate of up to 95% or more.

From the point of view of production efficiency, powder coating process is less, the main process is only three processes such as pre-treatment, electrostatic spraying and baking, which greatly shortens the production cycle, and the configuration of automatic coating machinery and recycling cycle system, it can form an automatic production.

In the coating, the film thickness can be controlled, a coating can be obtained 50 ~ 300um thick film, and is not easy to produce paint thick coating when the drip droop or stagnation (oil), does not occur solvent pinholes, does not cause thick coating defects, edge coverage is also higher.

Paint is generally a coating film thickness of 5-20um, if you want to get a thick coating film or high-grade requirements of the film, it must be coated several times to achieve. Compared with it, powder coating has higher coating efficiency.